There are many reasons why a water table should be used for plasma table. This is inexpensive, typically works without a dust collector, eliminates noise, arc flash that might prove to be dangerous, distortion related to heat, and cools the parts. Even though a table is built on old technology, the plasma cutting systems are sold with tables.

Some tables are just a tank that is filled with water and burning bars are placed on the top. But this does not allow the users to enjoy the advantages of plasma tables. The characteristics below are used to describe how the level of plasma tables can be changed.

What are the construction designs of a water table with plasma cutting?

The construction of the water plasma table is very simple. A very big chamber is constructed on the plasma table, under the burning bars and a tray made of steel. This chamber has openings inside the water plasma table in conjunction with its bottom edge; this allows the air to be trapped inside, which is very like a bowl being submerged upside down. After leading the air out from the chamber, the table is moved down or up.

- The water level at least can have a supply valve for air and release valve for air, which in turn the controls the compresses air let out or coming into the chamber. These valves are usually simple ball valves shaped like a ball that is operated by hands or these can be valves made of solenoid, which is controlled with the help of the CNC.

- To ensure the level of water in the table, the release value should be closed and the valve for supply should be opened. The air that gets compressed is pushed into the chamber, which in turn forces the water out through the openings located right at the bottom of the chamber. This results in an increase in the level of water. Once the water reaches a specific level, the air supply valve shuts down and air valve stays closed.

- To reduce the level of the water, the release valve should be opened whereas the valve for supply stays closed, which in turns allow the air to move out of the chamber. The total weight of the water causes the back flow into the chamber.

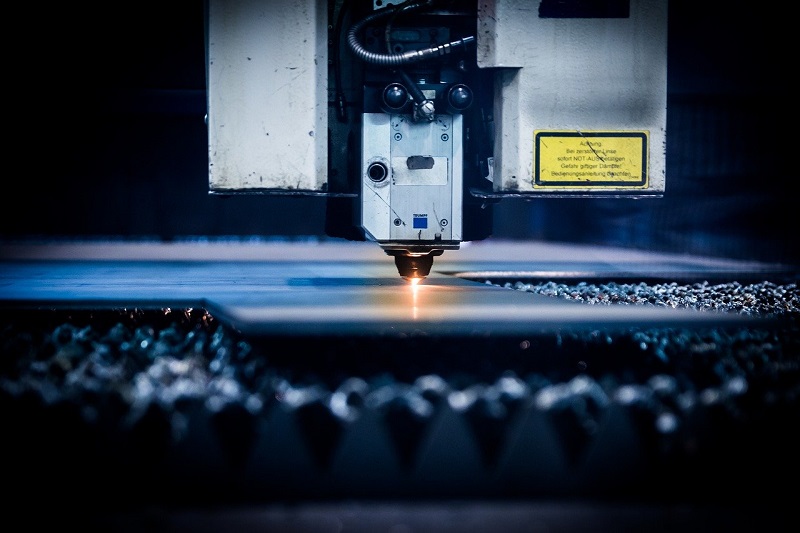

Under Water Plasma Cutting with The Help of Water Plasma table

This table is primary used for underwater cutting with the help of plasma. It depends on the design of the torch and vintage, with which the user may be able to submerge the entire torch and successfully make the required cuts without the assistance of any other equipment. However, most of the new oxygen plasma cutting systems requires the help of precision plasma system, which will require an air curtain that fits on the torch. The curtain made of air uses air that is compressed to create a bubble that covers the front end of the torch to protect the arc for precision cutting from water. Some of these plasma torches are not exactly designed for usage under water but can be still used to cut plates that is set about water.

For larger plasma tables, even if the cut is not made under water, a water table is still recommended. This allows lowering of the water for easy access and cleaning out small parts that usually drop between the bars that burn. Finally, for safety there are companies that manufacture certain tables for eye protection. Along with tables, the users should purchase safety gloves and aprons that protect the body during the cutting process.