The productivity, efficiency, and thus the future operational costs are directly influenced by the engine you choose. Among several diesel engines, Perkins engines have built a legacy of confidence and faith in their performance, durability, and all-around performance. If Perkins engines are going to make their way into your equipment or even for an upgrade while you’re in Western Australia, alongside the thought of updating some Perkins engines, it becomes very important how to choose the right Perkins engines Perth model in accordance with the needs of your business. Consider these prime considerations which will guide you into taking good decisions that will ensure operation of the engine at peak performance with attainment of overall business.

Understand Your Business Needs and Application

First and foremost, dig into properties of the Perkins engine model you want to get. Perkins engines are ubiquitous across industries. Construction, agriculture, mining, marine work, generating power, and industries for manufacturing industrial products all add that Perkins engines have the need for business applications: horsepower, torque, fuel economy, and emission standards different from one another.

What machinery or equipment will run off the engine? Small, light-duty machines, like a small agricultural machine, might operate with one of Perkins’s smaller engines. On the contrary, heavy-duty applications, such as mining or construction equipment, would call for a much larger and tougher engine model that can endure as punishing conditions and longer use.

This is an excellent time to note down all the operational requirements needed, the power output, the working environment, and the duty cycles, making the Perkins engines Perth model excellent in selection when it comes to the efficiency and reliability criteria for your engine requirement.

Study Engine Specifications and Features

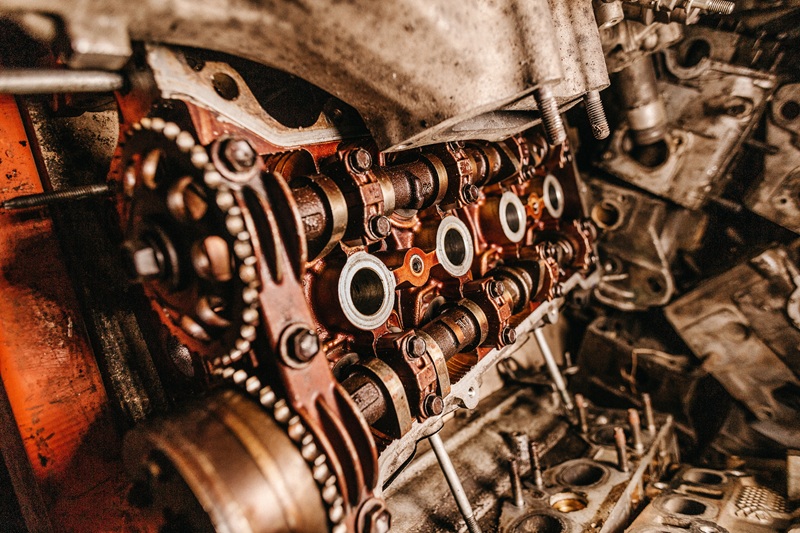

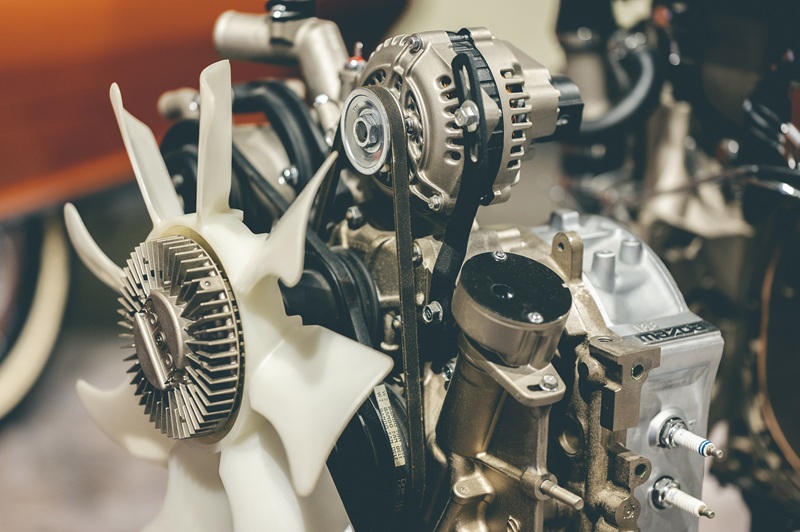

After identifying the business needs, the next thing is to find a match-up of engine specifications that would be in line with equipment requirements. Perkins engines are built in various sizes and configurations for the different power bands, types of fuel, and emission regulations.

Some of the key specifications one should check out include:

- Horsepower and Torque: Sufficient engine power to handle the maximum load and operating conditions of the equipment.

- Fuel Efficiency: Check for energy sources that enhanced optimize fuel energy consumption for a further lower operational cost and would be of importance when bringing heavy work into the engines.

- Compliance with Emissions: Perkins engages in the selection of engines that best suit compliance with limits such as Stage IIIC or Tier 4 according to the industry and zone.

- Durability Features: Robust components and improved cooling systems are key equipment to reducing downtime in heavy-duty applications.

- Maintenance intervals: In this case, longer service intervals prevent overhead costs by minimizing the frequency between services and providing additional time on the equipment.

Having these technical specifications tied up perfectly with your business need will ensure that the Perkins engine model selected will be a cost-effective and productive driver throughout its lifetime.

Consider Support, Parts Availability, and Service

Apart from a proper assessment of engine specifications and what one expects the engine to do; the right Perkins engines Perth model might entail everything in after-sales support right down to spare parts availability. The presence of genuine spares and an expert servicing team determines the engine’s health and keeps operational flow minimum with breakdown costs.

Business Engines models that hence are close and are backed by a strong guild of technicians and suppliers for quick diagnostics, repairs, and replacement parts enable the operators to direct their energies to their core activities while keeping them continuously running.

Thus, the engines with warranty coverage and technical support underwrite future performance while they give the business confidence to focus on daily operations.

Considering TCO and Lifespan

Of course, the first buying price of Perkins engine is worth considering by industry owners; however, they also must consider other costs calculated against fuel usage, maintaining almost permanent fuel quality, and occasional minor repairs, and probably even lifespan for their total cost of ownership calculations (TCO).

Generally, its high-quality Perkins engines are fuel-efficient and thus need less maintenance, translating into massive savings. Investment in a robust model of engine specifically rated for the workload in your company can greatly minimize risks of early deterioration; possibly giving maximum periods between overhauls.

When analyzed in this way regarding TCO, comparing upfront investment with performance return available will ensure that a company is able to select Perkins engines Perth models providing most value when it comes to sustainable growth.

Environmental and Sustainability Considerations

Since regulatory measures induce environmental aspects, the sourcing of Perkins engines must relate directly to the sustainability goals of a company regarding compliance with emissions regulations.

With the latest technologies applied by Perkins engines, such as electronic fuel injection, turbo charging, and exhaust gas recirculation, pollution has been reduced drastically while the power output has significantly increased.

Such Perkins engines that have complied with the environment will save you from eventually having to face stricter regulations and will keep away from your business hefty penalties and needless upgrades.

Conclusion

Selection of an engine model primarily Perkins Perth is a strategic decision which takes cognizance of operational requirements, engine capability, maintenance infrastructure, cost implications, environmental issues, among others. A good assessment of such factors enables the selection of an engine that does not only accomplish its performance needs at present but supports long-term efficiency and sustainability of the company.

By selecting the correct Perkins engine model among others, one is investing in a dependable, fuel-efficient engine that will be capable of improving production as well as reducing the chances of unforeseen downtimes. With the current informed analyses, engine decisions will echo operational success for businesses all over Western Australia and beyond.