Tool making is an activity that involves manufacture and production of useful instruments. The tools developed by such an activity can be simple as well as highly complex and technologically sophisticated. Tool making is an art, and it is also the application of the basic combinations of science, by using scrap metals and applying heat to them.

Uses of Tool Making

Tool making is heavily employed in making

- Moulds – which are further used for making different shapes.

- Dies – these are shaped blocks to cut, stamp and press other materials

How is tool making carried out?

The tool making process involves various steps. These steps are underscored below:

- The process kicks in with the development of technical drawings. Drawing board is the place where the inception step of the tool making takes place.

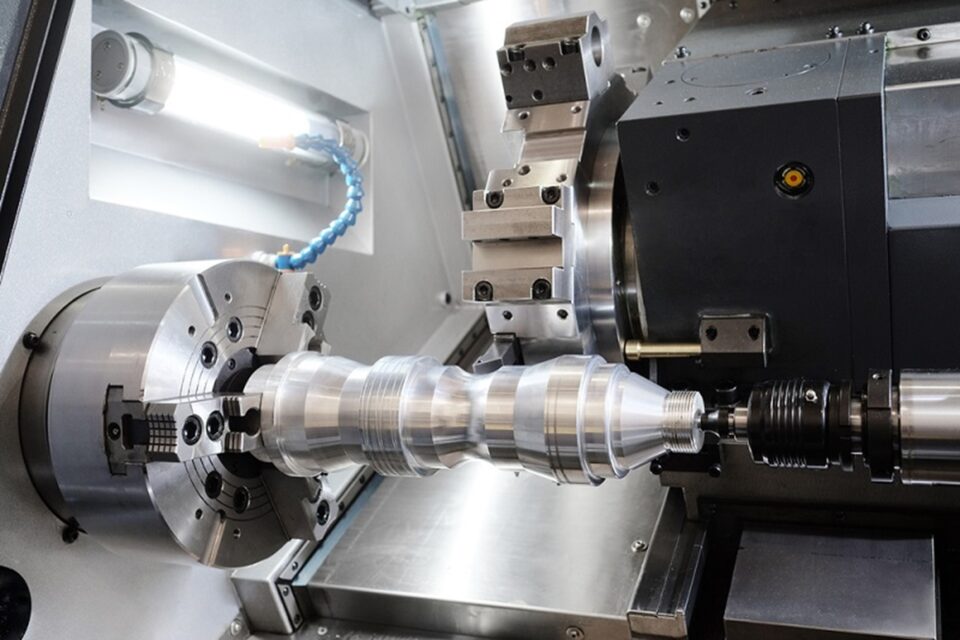

- The next step is employing specialized machines for shaping and developing the tools. This step involves the use heavy machines like Lathes, Computer Numerical Controlled (CNC) machines, grinding machines, milling machines and boring machines.

- The final step is that of providing a smooth finish to the tool. This step involves using small or hand tools like files, grinding and polishing machines to make the final product smooth, polished and removing any visible blemishes to the finished tool.

Use of multiple computer application techniques:

- Computing and digitization has become an indispensable part of any field. Manufacturing and tool making is no stranger to this technological advancement.

- There is extensive use of CAD, CAM, CNC and other computer-aided technologies in the manufacturing field. There is an increased demand of IT specialization skills in tool making field these days.

- Tool making specialists are required to have these entire computers aided IT skills along with traditional manufacturing skills.

- Tool making is a unique craft, and quite different from other manufacturing items, due to this very nature it is absolutely essential to design and fabricate special tools and customize those to adapt to tool making specifications.

Qualifications and Skill-set Requirement for tool making:

Tool makers have to go through a training program. There are various training programs but all follow some basic pattern. Many start with an apprenticeship programs with the employer. They combine classroom training as well as hands on experience. Some qualification in basic mathematics, science, engineering, science or design and technology can be very helpful in understanding the pattern or design and the method to craft it. It might take few years before one establishes himself/ herself as a renowned tool maker. Many go through 4 to 5 years of apprenticeship program in tool making to gain the required knowledge and experience. There are many institutions that offer tool making courses. NTMA (National Tooling and Machining Association) in United States offer various training programs. Students there go through 4 years of college course and get hands on experience of 10,000 working hours along with it to complete their apprenticeship program.

Jig/ Fixture Maker

- Jig and fixture maker falls under the broad category of tool and die maker. Jig is something that mounts onto a work piece.

- While a fixture has the work piece placed on it, into it, or next to it. A jig and fixture maker needs to have good knowledge of how to use various machines to build the devices.

- They need to have skills in welding and sometimes use wood working equipment’s. Most of the times, an engineer in building the tools advises them. The use of various metals and electronic devices can be used to make the machines last longer.

With the use of computers in modern age, the use of jigs in manufacturing has been limited but even then computer run machines need some sort of clamping fixture for production runs for tool making.

After reading this blog you have all the necessary information about tool making. If you still want to know more click here and get more information.